Our Services

Prototyping and Manufacturing with In-House Project Management

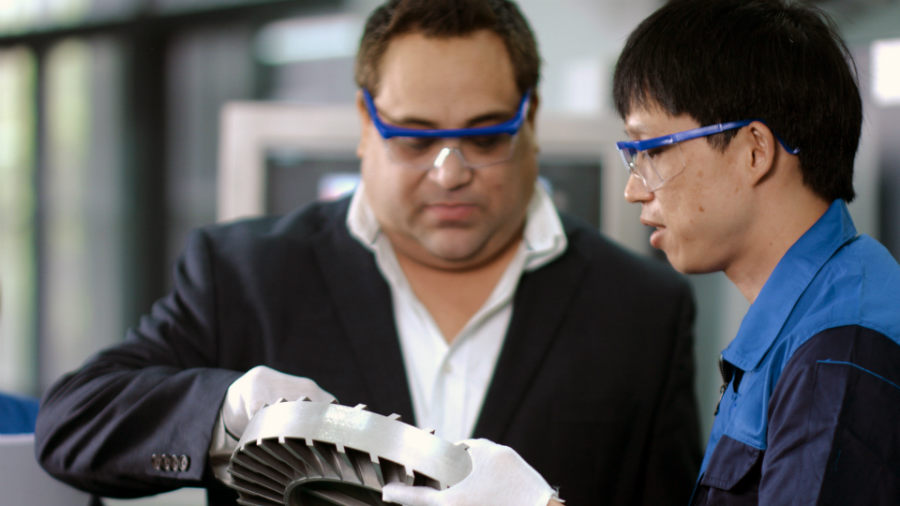

CNC Machining Services

To stay at the head of CNC manufacturing capabilities, we utilize the most-advanced machinery equipped with the latest in supporting software. Our engineers remain at the forefront of industry trends and development, resulting in unparalleled manufacturing capability. Using our collection of 3-, 4-, and 5-axis CNC machines we can serve a host of applications using a myriad of metals, alloys, and plastics. Have accurate, finished metal parts in as little as 2-5 days.

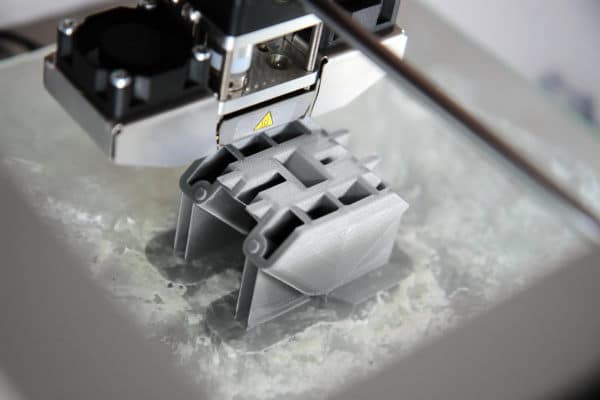

3D Printing Services

3D printing is the latest development in prototype creation. Using SLA and SLS printing, ZTL Tech can produce accurate, miniature, functioning representations of your design in just 24-48 hours! 3D porotypes are great for determining product function, explaining a concept, or impressing an investor.

Sheet Metal

Sheet metal is strong, malleable, and very popular. Sheet metal is resistant to both corrosion and heat. Multiple metals including tin, stainless steel, nickel, copper, and aluminum can be used in sheet metal fabrication. Sheet metal allows for the design and production of complex shapes and designs, placing parts made with sheet metal in advanced industries worldwide.

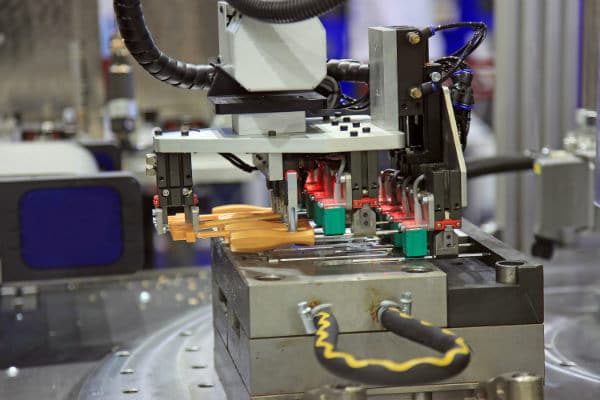

Injection Molding

Produce thousands of identical and complex plastic parts quickly with plastic injection molding services by ZTL Technologies. Parts made with plastic are chemically, biologically, and environmentally resistant making them useful across a massive span of industries. Plastic injection molding works with many different plastics, each of which can be finished for different effects in-house. We can create complex aluminum prototype tools in as little as 5-7 days. Production tools can be produced in 2-4 weeks using P20 steel.

Die Casting

Die casting forms metal materials into shapes made to your specifications. Dies are made in our CNC facility, then used to create identical metal casts. Casts are cooled and inspected, and many finishing services can be applied for utility and cosmetic purposes. We can produce Die Casted tools in just 2-4 weeks using H13 steel. We also offer: Leak Testing, Impregnation, Anodizing, Powder Coating, Inserts, secondary machining, and cleaning.

Silicone Rubber Molding

Items made using silicone rubber are resistant to corrosion, chemicals, unaffected by electricity, and durable under extreme conditions. In fact, Liquid Silicone Rubber (LSR) is in such high demand because it has uses in almost every industry across the globe. LSR is available in many colors, can be used in 3D printing, and can be used in injection molding to create thousands of units.

Finishing Services

We have an in-house finishing department capable of applying an incredible number of coatings and finishes to your completed projects. Finishing services offer increased visibility and durability for prototypes, small-batch manufacturing, and low-volume production. For specific color matching, we use the Pantone color matching system for extreme accuracy and seamless connectivity.