CNC Machining Services

Accuracy & Precision

ZTL Technologies provides advanced CNC machining services to the international market. We serve such a large market using over 200 CNC turning and milling machines at our facility. We have 3-, 4-, and 5-axis CNC machines equipped with the latest supporting software to create parts and components rapidly, and with incredible precision. Our massive bank of machinery allows up to approach a host of different projects over nearly every industry. For your CNC prototyping, small-batch, and low-volume production needs, ZTL offers competitive pricing with superior results. Our staff, software, and set of machines allow us to tackle even the most complex projects – we do not shy away from a challenge.

The advantages of CNC machining include:

- Accuracy, speed, repeatability

- Applicable over a massive span of industries

- Uses and supports alloys, metals, and plastics

- Prototype, small-batch, and low-volume orders

- Extreme precision

At ZTL Technology we believe that three components are necessary for perfection: Technology, design, and engineer talent. We combine all three to create parts for many industries, including:

- Medical

- Mechanical

- Automotive

- Aerospace

- Household

- Consumer Electronics

- Computers

- Robotics, and more!

Contact us today and see how ZTL Technologies can make your vision a reality!

CNC Machining – The Basics

CNC stands for Computer Numeric Control. The process uses computers to input data and measurements beyond human capability for extremely high-levels of precision. The process is supervised by talented engineers who assist with the data, measurements, and ensure the production process operates flawlessly.

A reductive process, CNC machining starts using a solid piece of raw material, and removes layers with extreme care to reveal your design. This can be done using one of two processes: CNC milling and CNC tooling.

CNC Milling and CNC Turning

Depending on your needs, your project may call for CNC turning or CNC milling.

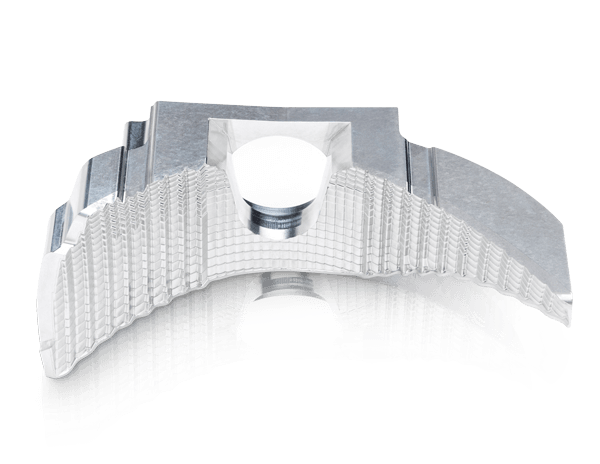

CNC Milling Process

The CNC milling process is the most common, used in creating designs of all sizes. Raw materials are fed into the milling machine which cuts the excess away. The raw materials are selected and measured to produce minimum waste, reducing production cost. Our engineers use the latest CNC machinery and controls to produce your design with speed and precision.

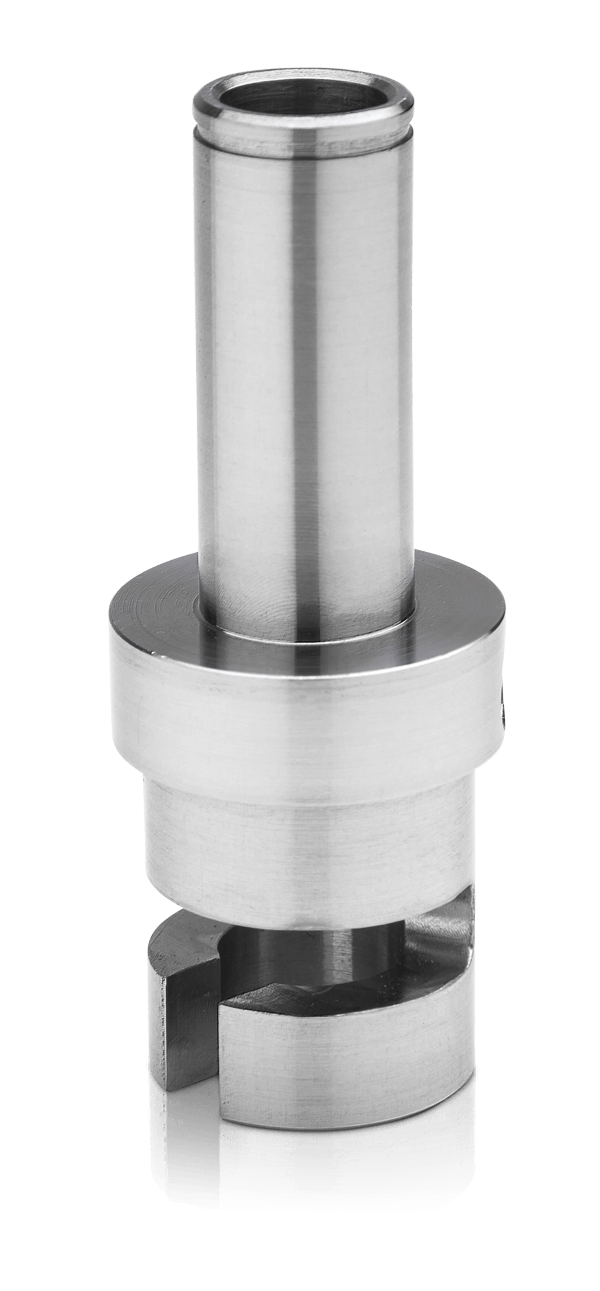

CNC Turning Process

The simplest CNC process, CNC turning uses a lathe, continually turning a piece of raw material as it is cut and bored. CNC turning is used to produce exact holes and groves.

Your project demands will determine which CNC process is best for you. Depending on your project, CNC machining services may be the manufacturing solution you require. For more information on what CNC services can do for you, if you’d like to know more about the benefits of CNC, or just have a few questions, call us today.

CNC Machining: Materials

An incredibly large variety of materials can be used in CNC milling and turning. The most commonly-chosen materials used in the CNC process are:

- Copper

- Titanium

- Polycarbonate

- ABS

- Aluminum

- Magnesium

- Stainless Steel

- Brass

- Nylon

- PMMA/Acrylic

CNC designs can be produced using dozens of additional materials – contact us today to discuss your options. We’d be happy to explain your material choices and production options with you!

At ZTL Technology we believe in putting our experience to work, for you. Together we can determine the best production solution to fit your needs. Let’s discuss your options!

Request a Free Quote

For a free quote for your CNC milling or CNC turning project, look no further. Our operation combines skill, machinery, materials, and passion for superior service and unmatched quality. Save on costs, waste, lead-time, and worry – contact ZTL Technologies today. With a CAD file, we can provide a free quote in just 12-24 hours. Let’s get started – call today!