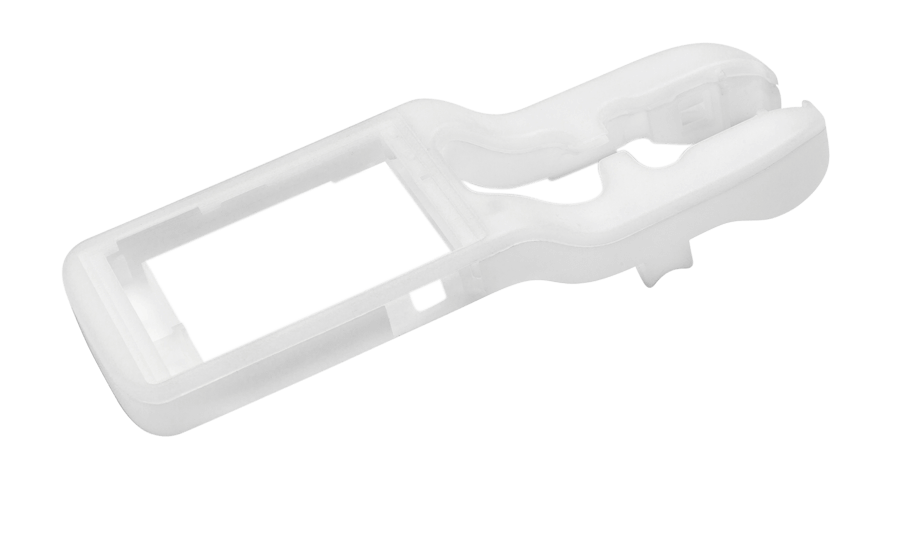

Plastic Injection Molding

Rapid Manufacturing of Plastic Parts

For the rapid manufacture of plastic injection molded parts, ZTL Technologies offers complete manufacturing solutions all under one roof. A multitude of plastic materials are available to be used in the plastic injection molding process. Additionally, completed plastic parts can undergo multiple surface finishes extending their use, range of capabilities, and enhancing their appearance.

Once a mold is created, literally thousands of identical plastic parts can be made using it. This helps increase efficiency, decrease costs, and get your product in your hands faster. Plastic injection molding has uses across nearly every industry imaginable, including:

- Automotive

- Aerospace

- Home Goods

- Medical

- Robotics

- Consumer Electronics

- Defense

- Engineering

Plastic parts are used in nearly every industrial application! If you need it made, come talk to us. Plastic injection molding is a simple and cost-effective solution for small-batch and low-volume manufacturing.

Plastic injection molding produces high-quality plastic parts:

- in a variety of custom shapes, sizes, colors, and textures

- strong enough to weather extreme conditions

- built to last

Plastic Injection Molding – The Process

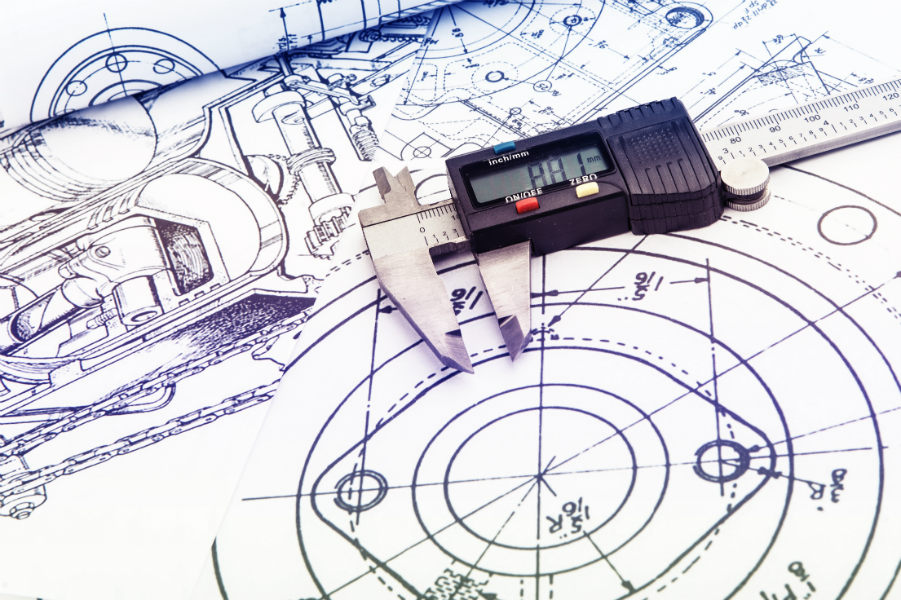

Design

Every project starts with an idea. Whether you have a CAD file ready, or need assistance taking your idea and turning it into a design, ZTL Technologies is ready to assist! Plastic injection molded parts might be part of a small inner-working, or the focal point of your entire product. In every case, you have our full attention. Our team can aid in design, help with material selection, or help in any way you require – we are here to serve you! Once your design is ready for production, your mold is created.

Mold Creation

Your mold is not your finished product. It is the mold with which we will rapidly produce thousands of identical copies of your finished product. Your mold is created in our own CNC department, reducing time and costs. The mold is a hollowed-out cavity, built to specification, using our CNC and EDM machines.

Molding

To create plastic parts, molds are filled with plastic pellets, then superheated and injected to form a solid mass within. Once it cools, the plastic part encased in the mold is built precisely to your design specification.

- Your design may require a process called Overmolding, the layering of multiple polymers into one mold for added color, texture, and strength.

One mold can produce thousands of identical units.

Finishing and Shipping

We offer a full range of finishing options to add protective and decorative layers to your plastic parts. After completion, parts are professionally packaged and shipped. All shipments are tracked ensuring you receive your shipment in a safe and timely manner.

Let’s Talk About Your Next Project or Idea

Let’s talk about your concept! Whether it’s an idea, design, or you’re ready to start manufacturing today, we are ready and willing to assist. For a free quote and DFM, contact ZTL Technologies today.